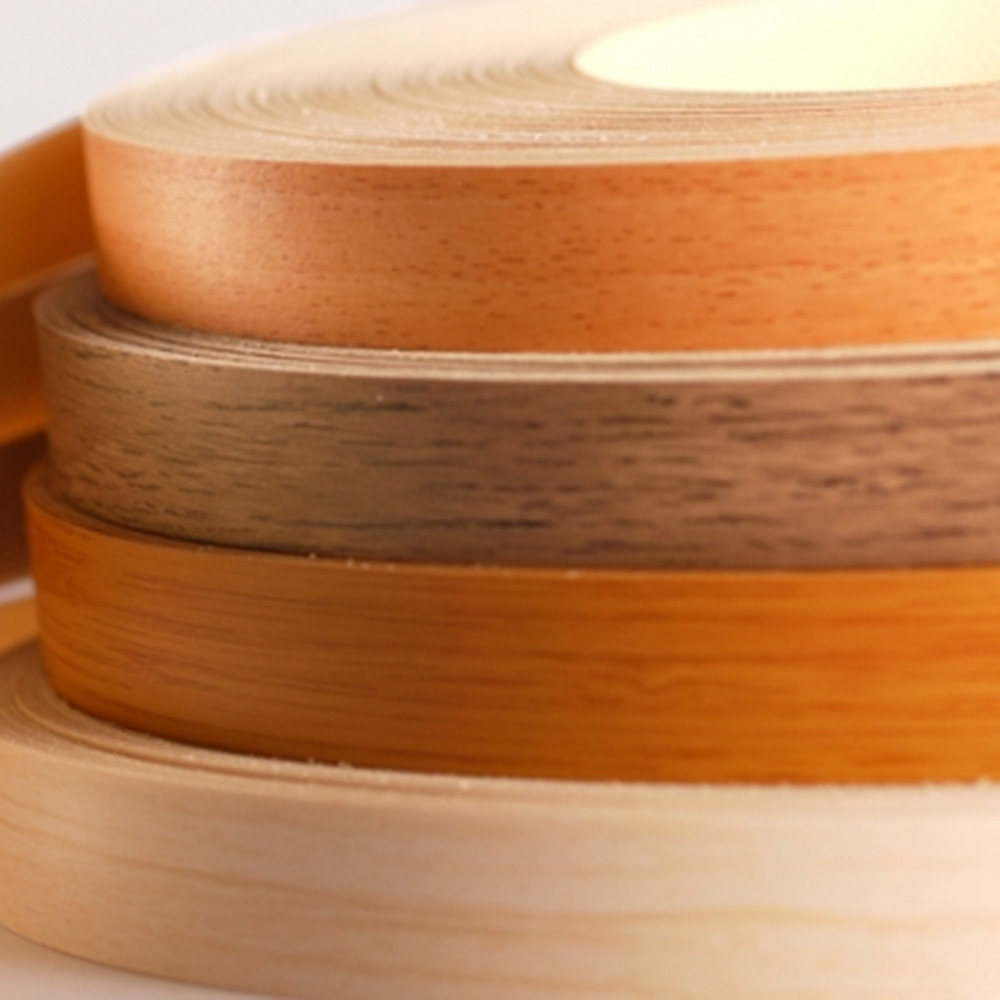

Edge band

Edge banding is used for two reasons: durability and aesthetics. Raw, unfinished edges of plywood and particle board are easier to damage. Edge banding, using either the veneer or solid wood options, reinforces the sides of the piece it is attached to, helping it survive wear and tear better than unfinished wood and protecting it from the elements. Now, you might not think the inside of a cabinet gets as much wear as, say, a tabletop, but when you’re regularly moving pieces in and out of a cabinet or changing shelf heights, it can affect the quality of the piece more than you think. Edge banding can withstand regular bumps, scrapes, and knocks much better than raw edges.

ABS edge banding

If you’re looking for the perfect edging solution, ABS edge banding, also known as Acrylonitrile Butadiene Styrene, is a terrific, adaptable thermoplastic option. ABS is one of the more modern edge banding materials available…

Melamine Edge Banding

Melamine edge banding, in addition to being decorative, serves as a sealer and is resistant to water, high temperatures, and UV exposure. This product’s longevity and durability have been thoroughly tested…

PVC Edge Banding

PVC Edge banding offers a surprising number of applications, including general interior design, exhibition stands, restrooms, kitchens, and office buildings. The PVC raw material, in addition to straight-line processing…

Veneer Edge Banding

Edge banding in veneer. Thick edge banding refers to all edge banding that is 1mm-2mm-3mm thick. This is a layered product with a uniform colour on the interior layers but is not usually made of the same wood as the surface veneer…