UV Excimer MDF

Materials: poplar or pine

Thickness: Tolerance ± 0.2mm

Water Absorption Expansion: ≤10%

Thickness: 3mm – 25mm

Size:1220*2440mm, Customized sizes

Glue: E0, E1, E2

Density:>730kgs/m³ for 7-25mm thickness;

>820kgs/m³ for 2-6mm thickness.

Surface Finishing: High glossy, Smooth, Matt, Embossed

Face & Back: Melamine Paper, Natural Wood Veneer, HPL, UV

Send Request

UV Excimer MDF

The UV Excimer MDF refers to the use of excimer curing technique on the plate’s surface, and has nothing to do with the substrate type. It is the plate’s surface effect treatment technology.

After absorbing 172 nm UV light, the acrylic double bond in the UV coating formulation can create free radicals (in the absence of a photoinitiator). At the same time, because the 172 nm UV penetration depth is just 100 to 500 nm, only a very thin layer of the coating is cured. This thin layer will shrink due to polymerization and crosslinking, resulting in an uneven surface. And the essence of excimer curing is to float on the underlayer of uncured liquid to generate a matte surface look.

Quality features

1.UV Excimer MDF technology: employing Italy’s top CEFLA Saifo spray line, as well as excimer nano super fog surface technology.

- Aldehyde-free environmental protection: the uv excimer mdf sheet is all ENF level, F4 star base material, utilising ultra-environmental zero aldehyde added MDI adhesive, five poisons harmless, super environmental protection, and silent usage.

- Easy to clean: decontamination leaves no scars, the finish has a high density of dense layer due to the unique vertical surface lacquer technology, unique nanotechnology to stain, oil stains, and plate is difficult to penetrate, easy to wipe! As good as new.

- Anti-fingerprint: the excimer improves surface performance by utilising the saturated water vapour pressure in the air (E), resulting in a surface devoid of lines.

- Surface thermal repair: uv excimer mdf board has the power of self-thermal healing, microscopic surface structure contains unique molecular components, easy repair tiny scratch area, so that it can be restored to its original smooth and smooth.

- 4H hardness: The uv excimer mdf panel has imported super wear-resistant hot melt paint combined with excimer, so the surface has a hard feature of wear resistance and scratch resistance, resulting in a 4H surface hardness.

- Soft touch: uv excimer mdf panel treatment with the leading excimer atomization technology, the surface combined with the application of multi-layer coating and nanotechnology, after the import of equipment sanding perfect solution to the surface smoothness, so that the surface feels as smooth as baby skin, comfortable, and natural.

- High colour firm: nanotechnology treatment to generate a unique reflection on the surface, can scatter ultraviolet radiation, so it keeps a dazzling look for 10 years like a day.

- 360° no reflection: delicate and elegant super matte finish effect, long-term affinity.

- Chemical corrosion resistance: UV excimer mdf has a highly stable surface finish and is resistant to acid and alkali corrosion from chemical substances and kitchen waste.

Application

Home decoration, such as shutters for the kitchen, living room, wardrobe, or bedrooms.

Comparison with UV and PET

The plate industry currently has three main production procedures for skin sensing boards: flat paste line, film pressing line, and excimer skin sensing.

To do dumb plate with flat paste line is first to the workpiece surface for double-sided dust removal treatment, to prevent the finished product surface from having raised dust particles, and then preheating treatment of the plate, to reduce the PUR adhesive coated to the surface of the plate when the temperature difference between the plate and the plate, after the plate preheating is completed for PUR adhesive coating and adhesive scraping smooth,

At the same time, the PUR adhesive is heat preserved, and the sheet or roll PET is glued on the plate before entering the four-roll rolling machine for pressing and pasting. Finally, the discharge is completed according to technological specifications by techniques such as mitre cutting, trimming, and film coating protection.

To do the film line dumb board, first remove the board dust, and then roll the board surface coated with a layer of UV paint into the moulding machine. The moulding machine’s pressure wheel will push the PVC skin sensitive film against the UV paint on the board. While pressing, the film and UV lamp can smooth the paint surface and cure the surface.

The PVC skin sensitive film adhered to the lacquer surface is subsequently removed by the film roller at the moulding machine’s outlet, leaving only the UV paint coating on the board, which is then fully cured by the double lamp or three lamp UV drier. Finally, the material is sliced and the protective film is removed.

1220x2440mm UV Excimer MDF Panel

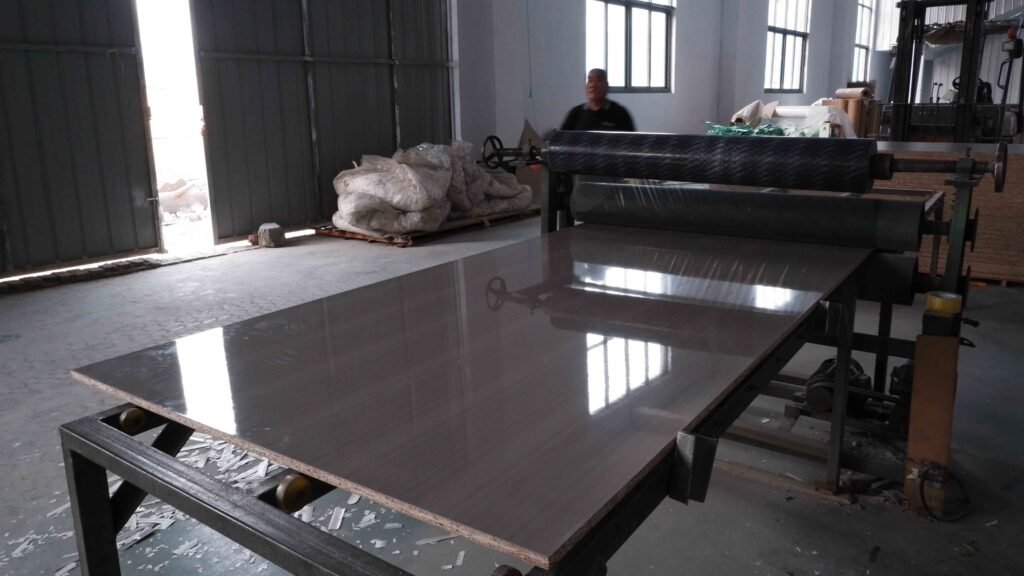

UV Excimer MDF Production process

Step 1: Clean the substrate, apply primer, and cure with UV light.

Step 2: After drying and curing, the base material is frosted, powdered, and matte-coated.

Step 3: The matte-coated substrate is first irradiated with LED precure and then treated with an excimer lamp for matte treatment.

Step 4: the substrate following matte treatment for UV drying and curing, i.e. the 0.5-2 excimer skin sensitive decorative panel’s matte luminosity

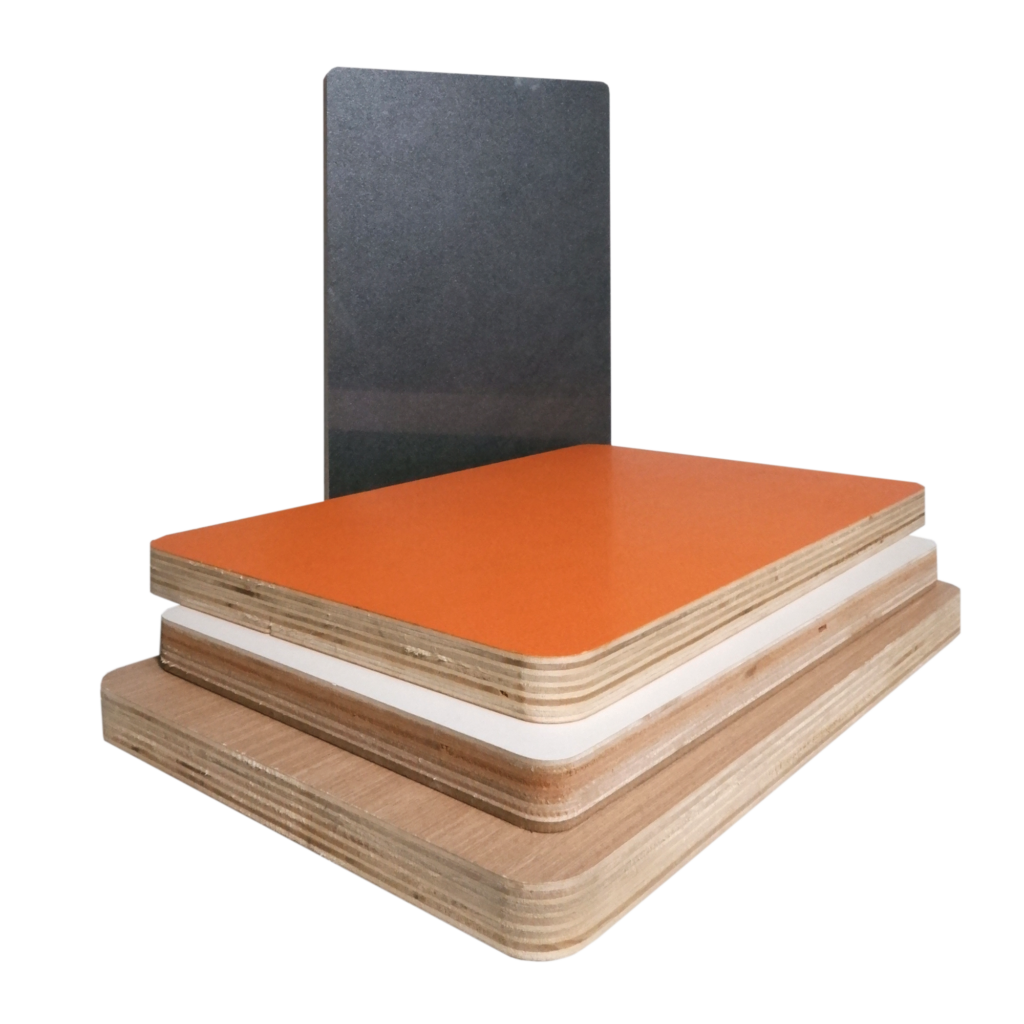

UV Excimer MDF Free Sample

We manufacture sample boards for many different customers, suitable for a range of different melamine sheet,hpl panel,uv board,fancy plywood,marine plywood,RV plywood,particle board,mdf board etc.

Typically 18mm thick 200mmx200mm plywood or particle board is used, but can be manufactured in any thickness or material requested.We can also help you design sample plates, or sample plate displays.

Lend time: Delivery time about 7-20 days.

Tons of possibilities including:

* Custom melamine Colors

* Custom size

* Custom Lamination

* Custom Veneers available

* Finished or treated edges

* Custom logo(acceptance of agency)

* Custom Decals

All sample boards are CNC manufactured to ensure quality.

We are growing our range each and every day so please do get in touch if you can’t find what you are looking for.Contact us for volume discounts

Get a inquiry

You can order samples of the designs you like so you can see them, feel them and test them for yourself before making your order. If you decide to order your front through us,the samples you get are free of charge, only bear the cost of sample delivery.

UV Excimer MDF Design

Melamine paper from Foresmate offers the advantages of any imitation of diverse designs and vibrant colour. Triamine paper may generate a range of decorative effects based on the varied steel plates of decorative paper used during hot pressing, such as smooth surface, hemp surface, relief, cloth pattern, corrugated, ray, synchronous flower, and so on.

If you believe you could profit from our design, please do not hesitate to Contact Us, since we are always looking for exciting projects and collaborations.

Melamine paper

We have our own professional and perfect team of designers, who update the surface design of different effects and colors every month, including wood grain, stone grain, solid color, marble grain, leather grain and so on.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.