Uncovering the mystery of laminated Plywood: everything you need to know

What is Laminated Plywood Made of?

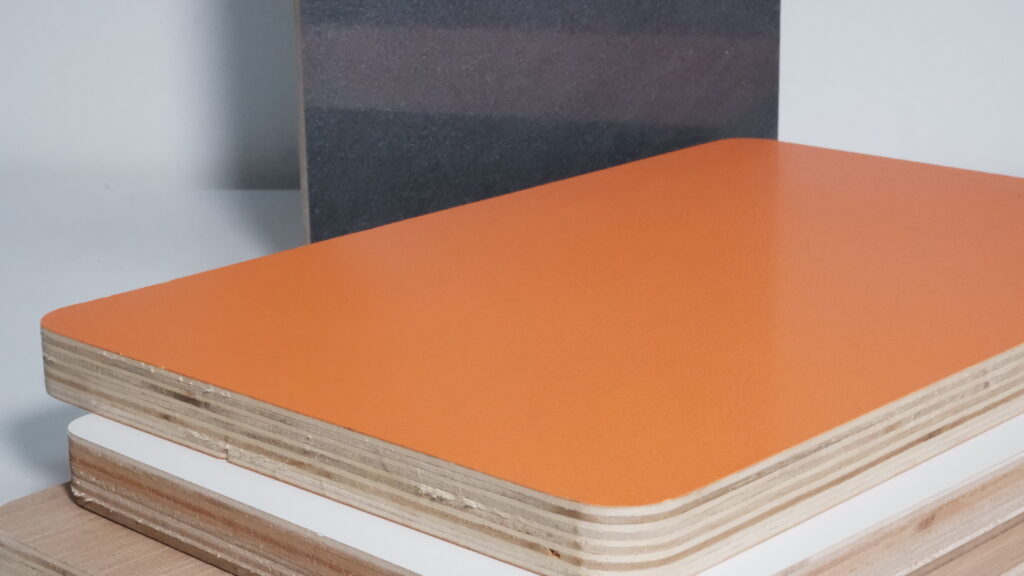

Melamine plywood is made by combining a thin layer of melamine resin with a core panel of plywood. The melamine resin is a type of thermosetting plastic that is known for its durability, moisture resistance, and heat resistance. The core panel of plywood is made up of layers of wood veneers that are glued together with an adhesive. The resulting product is a strong, durable, and versatile material that can be used for a variety of applications.

Melamine board is available in a range of colors and patterns, making it a popular choice for furniture, cabinetry, and interior design projects. It can be used in both residential and commercial settings and is often chosen for its affordability and ease of maintenance.

Advantages of Using Laminated plywood

One of the main advantages of using laminated plywood is its durability. The melamine resin coating makes the plywood resistant to scratches, moisture, and heat, making it an excellent choice for high-traffic areas. It is also less prone to warping and cracking than solid wood, making it a more stable option for construction and furniture projects.

Melamine coated plywood is also easy to clean and maintain. Unlike solid wood, it does not require regular sanding or refinishing to maintain its appearance. A simple wipe down with a damp cloth is all that is needed to keep it looking clean and new.

Another advantage of melamine plywood is its affordability. Compared to solid wood, melamine faced plywood is a more cost-effective option, making it a popular choice for DIY projects and budget-conscious homeowners.

Disadvantages of Using Melamine Plywood

While melamine plywood has many advantages, it is not without its drawbacks. One of the main disadvantages of using melamine sheet is that it is not as strong as solid wood. While it is a durable material, it may not be suitable for heavy-duty applications or structural projects.

Another disadvantage of laminated plywood is that it can be challenging to cut and shape. The melamine resin coating can chip or crack when cut with a saw, so it is important to use the proper cutting tools and techniques to avoid damaging the material.

Finally, while melamine plywood board is available in a range of colors and patterns, it may not offer the same level of customization as solid wood. If you are looking for a unique or custom finish, solid wood may be a better option.

Different Types of Melamine Plywood

Melamine on plywood is available in a range of colors, patterns, and textures, making it a versatile option for a variety of projects. Some of the most common types of plywood with melamine include:

White Melamine Plywood

White melamine plywood is a popular choice for cabinetry, shelving, and furniture projects. It has a clean, modern look that complements a variety of design styles.

Woodgrain Melamine Plywood

Woodgrain melamine plywood is designed to mimic the look of natural wood. It is available in a range of colors and patterns, making it a popular choice for furniture and cabinetry projects.

Textured Melamine Plywood

Textured laminated plywood is designed to add depth and dimension to a project. It can be used to create a variety of effects, from a subtle texture to a bold, dramatic finish.

How to Choose the Right Melamine Plywood for Your Project

When choosing laminated plywood for your project, there are several factors to consider. First, consider the application. Will the plywood be used for cabinetry, furniture, or a construction project? This will help determine the thickness and strength needed for your project.

Next, consider the finish. Do you want a white, woodgrain, or textured finish? Consider the overall design and color scheme of your project to determine the best finish for your needs.

Finally, consider the quality of the plywood. Look for plywood that is made with high-quality materials and has a smooth, even surface. Avoid plywood that is warped or has visible defects.

How to Cut and Install Melamine Plywood

Cutting and installing laminated plywood requires some special considerations. Because the melamine resin coating can chip or crack when cut with a saw, it is important to use the proper cutting tools and techniques.

When cutting 4×8 melamine sheet, use a sharp blade and make slow, even cuts. Use a blade with a high number of teeth to minimize chipping and cracking.

When installing laminated plywood, use screws or nails to secure it in place. Be sure to pre-drill the holes to avoid splitting the plywood. Use an adhesive to help secure the plywood to the surface, and be sure to use clamps to hold it in place while the adhesive dries.

Maintenance and Cleaning Tips for Melamine Plywood

Melamine plywood is easy to clean and maintain. To keep it looking its best, simply wipe it down with a damp cloth as needed. Avoid using abrasive cleaners or scrubbers, as these can scratch or damage the surface.

If the plywood becomes scratched or damaged, it can be repaired using wood filler or a melamine touch-up kit. Simply fill in the damaged area and sand it smooth before touching up the finish.

Frequently Asked Questions About Melamine Plywood

Is melamine plywood waterproof?

While laminated plywood is moisture-resistant, it is not waterproof. It may not be suitable for use in areas that are consistently exposed to water.

Can melamine plywood be painted?

Yes, melamine plywood can be painted. However, it is important to properly prepare the surface by sanding and cleaning it before applying paint.

Can melamine plywood be stained?

No, laminated plywood cannot be stained. The melamine resin coating prevents the wood from absorbing stain.

Conclusion

Melamine plywood is a durable, versatile, and affordable option for a variety of projects. By understanding the advantages and disadvantages of this material, as well as the different types available, you can make an informed decision for your next project. Whether you’re a professional contractor or a DIY enthusiast, melamine plywood is a great choice for cabinetry, furniture, and construction projects. So, go ahead and give it a try!